DESIGN & PRODUCT ENGINEERING

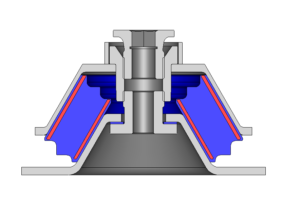

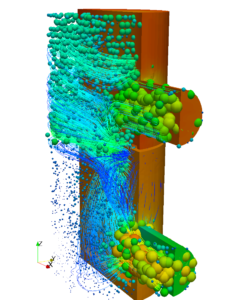

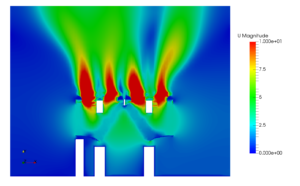

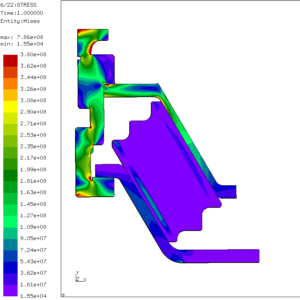

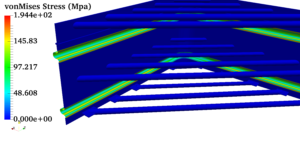

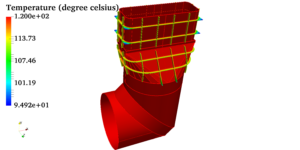

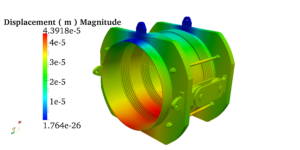

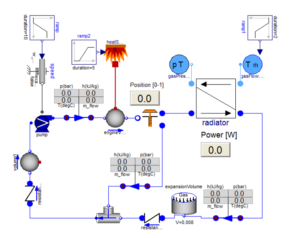

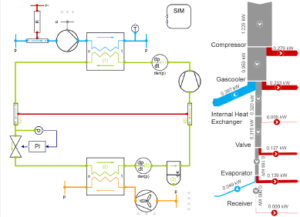

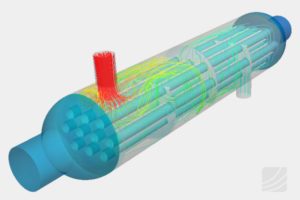

We design and analyze (FEA & CFD) pressure vessels, heat exchangers, bellow expansion joints and other process equipments as per the standards e.g. ASME, Expansion Joint Manufactures Association (EJMA), Indian Boiler Code etc.

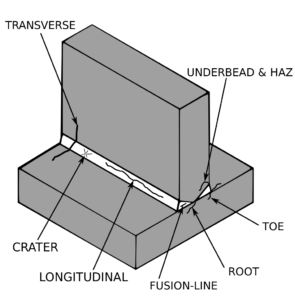

As a part of Failure analysis approach, different modes of failures are analyzed for structural integrity as per the British Standard (BS) / European standard/ American standards. Our team has good expertise in welding analysis, fracture & crack analysis for residual life estimation, crack initiation and propagation in polymers.

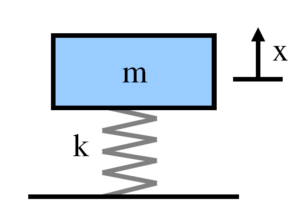

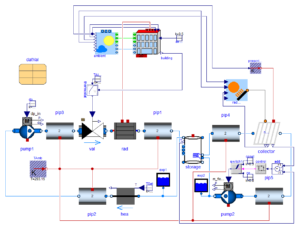

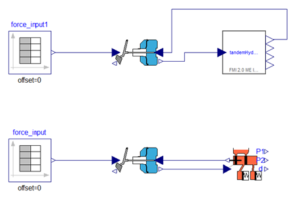

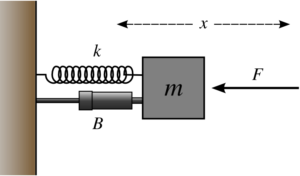

The Design & Product Engineering services encompasses product stress and durability analysis, failure analysis, noise and vibration studies, impact/crash studies, multi-body dynamics, computational fluid dynamics (CFD), and optimization. We also provide end-to-end CAE services, and facilitate new product development (NPD) projects through precise design and prototyping.

As markets have become significantly more competitive and having small gains in performance can make or break success. Optimization techniques can be used to improve product performance and reduce cost. Along with the Optimization, Sensitivity analysis also very important to ensure overall performance for the design. Some designs may have great performance under ideal manufacturing and environmental conditions, but minor variations quickly degrade this.

Our approach

Create/ Innovate

Detailed Design

Simulate / Validate

Prototype

Optimization

Build/ Produce

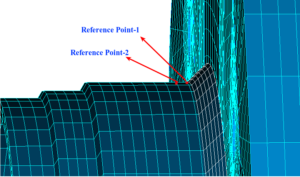

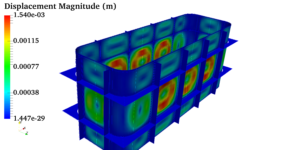

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.

Pressure vessels, pipes, expansion joints etc. are basic equipments for process industries. Pressure vessels are vessels working under internal, external or vacuum pressure, and possibly subjected to high temperature. Proper design and analysis is very important for the pressure vessels, as their failure can cause lot of hazards. Codes/ standards are used in the design phase, followed by analysis to ascertain stresses are within the allowable range. ASME provides wide range of guidelines for the proper design of such vessels.

BC. This book is a treatise on the theory of ethics, very popular during the Renaissance. The first line of Lorem Ipsum, “Lorem ipsum dolor sit amet..”, comes from a line in section 1.10.32.

BC. This book is a treatise on the theory of ethics, very popular during the Renaissance. The first line of Lorem Ipsum, “Lorem ipsum dolor sit amet..”, comes from a line in section 1.10.32.